MEB-3200C Series

Buttonholing Machine

Computer-controlled, Eyelet Buttonholing Sewing System

(Trimmer for Needle and Looper Thread with gimp)

The digitally controlled machine permits the selection and setting of various eyelet shapes.

We thoroughly pursue operability and realized easy operation with a new operation panel.

Description

Color LCD touch panel for intuitive operation

Configured with a large, highly visible color LCD touch panel for instant display of the stitch shape, set values, and menu settings for the sewing functions. Fast, intuitive touch-panel operation reduces the time taken to set the data and eliminates mistakes in sewing and machine operation.

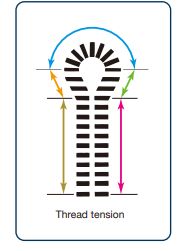

An active tension mechanism (computer-controlled thread tension mechanism)

Electronic control of the needle/looper thread tension

Needle and looper thread tensions can be digitally established on the operation panel according to sewing conditions. The machine also ensures the consistent production of high-quality seams.

• Data registration on a pattern-by-pattern basis

• Easy reproduction of the same sewing conditions

Using conventional machines, it’s often quite difficult to reproduce the same sewing conditions. This machine does it with ease. With this capability, the MEB-3200C responds immediately to material changes, significantly reducing the time required for setup changes or adjustments. The machine also ensures the consistent production of high-quality seams. With the further improvements achieved, the pressure fluctuations are reduced during sewing to increase the stability of the thread tension. And with the very small differences in thread tension between sewing machines, the same thread tension can be obtained using the same sewing data.

Thread tensions can be separately established for various sections of a buttonhole such as eyelet sections and parallel sections

● The machine promises high-quality seams by smoothly responding to changes in stitch formation and allowing the operator to set a separate thread tension for the bartacking sections of buttonholes.

● Thread tensions for the beginning and end of sewing can also be separately established. This helps prevent loose stitches or slip-off or raveling of thread at the beginning of sewing.

Easier threading

Threading work, a cumbersome process with conventional eyelet buttonholing machines, is now made easier with an air gun to blow the thread.

Management of sewing performance and sewing machine by the utilization of IoT (Internet of Things)

Management, browsing and editing of data can be carried outon the application software

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially-available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes. The operation panel is also provided as standard with a USB port. Data management and software update can be carried out with ease using a USB thumb drive.

Automatized knife pressure

The pressure of the cloth-cutting knife is now controlled automatically. Once the pressure is set, it holds steady even when the knife guard height or other conditions are changed. The steady control achieved eliminates the need for knife pressure readjustment when the knife guard is changed or repaired. The setup changing time is substantially reduced. (A different knife pressure can be set for every sewing pattern.) The automatized knife pressure control, together with the active tension of the needle and looper threads, significantly reduces manhours when skilled workers are in short supply.

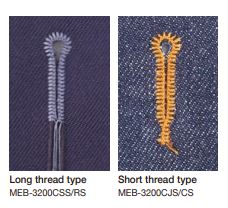

Consistent overall thread-trimming mechanism

When the MEB-3200CSS/RS for men’s and ladies’ wear trims the needle thread, looper thread, and gimp, it leaves a long strip of thread/gimp remaining on the material. With a sufficient length of thread/gimp to hold by hand, the operator can easily carry out the bartacking in the next process. When the MEB-3200CJS for jeans and MEB-3200CCS for cotton pants / work pants trim the needle thread, looper thread, and gimp, they leave only a short thread/gimp on the material. With no thread nipping required, work efficiency and productivity are both improved.